BABY CARE

ADULT INCONTINENCE

DAILY CLEANING

- Wet Wipes Machine

- Compressed Towel Machine

- Bath Towel Machine

SPECIALTY

- Packaging machine

- Nonwoven Embossing Machine

- Nonwoven Perforating Machine

- SAP Paper Machine

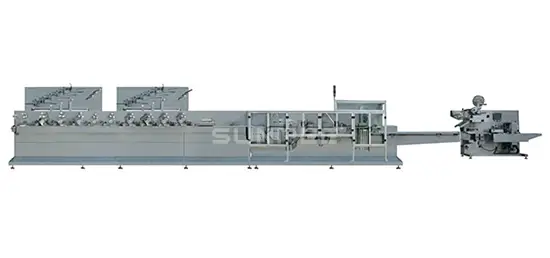

We have professional converting solutions for various wet wipes you can find on the market. With full experience engineering team, in-house machining and designing capabilities, we can fulfill your customization needs for your wet wipes machine, from running kinds of substrates with ease to high-speed cutting processes that eliminate material waste, and low-impact folding processes that maintain quality. Ultimate product flexibility, ability to process new-generation flushable substrates.

| PRODUCT | PRODUCTION SPEED | |

| 1-2pcs | 250-300 counts/minute | |

| 5-30pcs | 850-1000 counts/minute | |

| 30-120pcs | 450-480 cuts/minute | 55 (bags/minute – 80pcs) |

| 30-120pcs | 450-480 cuts/minute | 90 (bags/minute – 80pcs) |

By understanding your need, down to the smallest detail, then channel our activities in a responsible and reliable way to deliver tailor-made wet wipes machines. This list represents base configuration machines, we have complete design capabilities and can meet every one of your specific requirements. Welcome to contact us now!

Through a collaborative process, SUNREE takes into account your wet wipes product and production requirements to ensure an optimal solution that scales with your needs, including baby wipes, antibacterial wipes, makeup remover wipes, refreshing wipes, household wipes, alcohol swab and so on. Wherever in the world you may be, experience our passion for finding new ways to help you be successful in increasingly competitive markets.

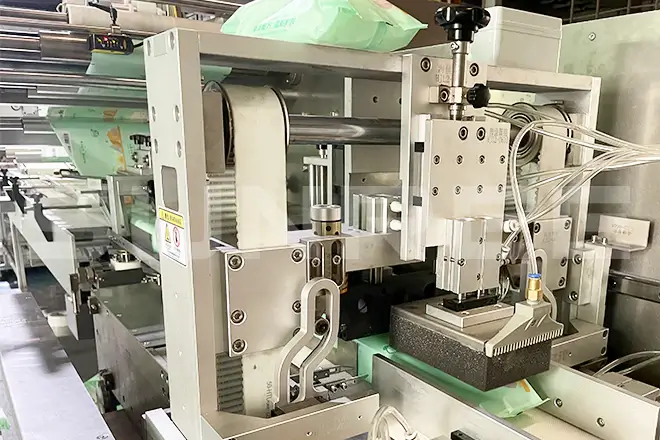

A full servo drive system can help to lower the noise levels during production, reduce wet wipes machine maintenance costs, and improve stability during high-speed production by providing precise control over the production process. New folding device features a patented design that allows for easy adjustment of the folded width and folding method, make it well-suited for new flushable wiper folding technique.

The wetting flow control system allows for the precise setting of the amount of liquid applied, which can be easily set on the HMI touch screen. It provides real-time display of the liquid level, ensuring that the process is closely monitored and controlled. The liquid alarm is controlled by sensors, which automatically trigger backflow from the standby liquid tank when the liquid reaches the set value, ensuring that our wet wipes machine system operates safely and efficiently.

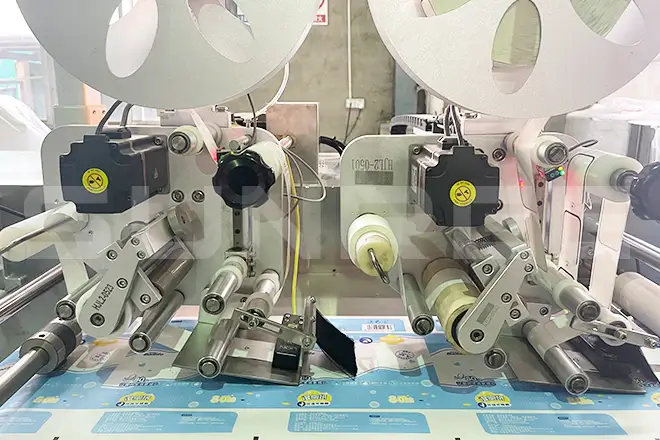

The wet wipes package label feeding system includes tension control and USA Lion sensors to ensure accurate and reliable label automatic conversion without stopping. AB label can be switched automatically with the pneumatic brake function when the set value is reached.

Equipped with web guide controller to maintain the position of the wet wipes packaging film at high or low speed, and three sets of central heat-seal devices use new electronic temperature control and the latest horizontal heat-seal technologies to achieve precise temperature control to ensure the good appearance of the package.

Using an advanced robot, the wet wipes package lid application speed can be 75 lids per minute, 4 slots for lids storing, max of 700 lids to realize automatic conversion. The lid label feeding system includes tension control and USA Lion sensors.

We have helped customers in more than 60 countries to be successful and improve their qualification rates. We also welcome you to send an inquiry for your needs, let us make your demands come alive.

Tell us what kind of support you need, we will reach out to you within 1 working day, please pay attention to the email with the suffix “@sunreechina.com”.