BABY CARE

ADULT INCONTINENCE

DAILY CLEANING

- Wet Wipes Machine

- Compressed Towel Machine

- Bath Towel Machine

SPECIALTY

- Packaging machine

- Nonwoven Embossing Machine

- Nonwoven Perforating Machine

- SAP Paper Machine

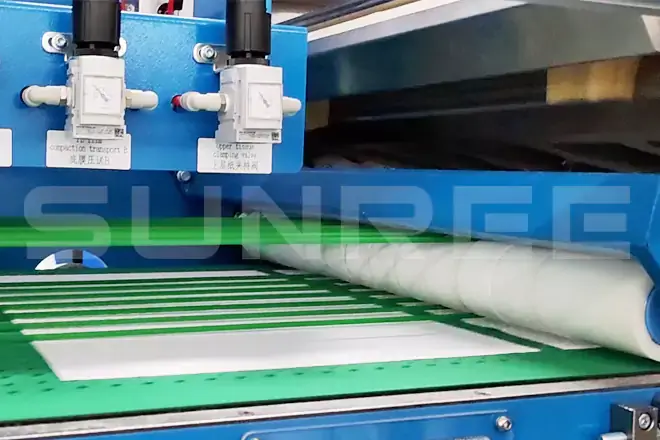

Thick or thin underpad, our machine provides versatility for many different underpad sizes and folding capabilities. Consistant distribution of super absorbent polymers across the area of the absorbent core is expected and advance capabilities that add value to disposable under pad like super wide core formation and core embossing are also possible.

| PRODUCT | LENGTH (MM) | SPEED (M/M) | |

| Underpad | 400 to 1200 | 200-350 | |

By understanding your need, down to the smallest detail, then channel our activities in a responsible and reliable way to deliver tailor-made underpad machines. This list represents base configuration machines, we have complete design capabilities and can meet every one of your specific requirements. Welcome to contact us now!

We provide a wide range of options to meet your underpad product requirements, our underpad machine is designed to seamlessly handle upgrades as technologies evolve with minimal investment and downtime. 24/7 worldwide service and online support solutions are provided to accelerate the troubleshooting process of underpad machine.

The sequential startup process reduces waste, and automatically splice raw materials without speed down and auto rejection during production to improve efficiency, auto splicing and manual splicing are both available, the splicing speed of each material can be set on touch screen. Advanced solution enabling you to run low basic weight materials to lower the consumption of incontinence underpad.

Integrated with all machine processes and customized to underpad being manufactured, the vision control system automatically rejects single underpad when underpad inconsistencies are detected, significantly reducing material waste and guaranteeing underpad quality throughout production.

With safety framework and cutter entrance safety cover, and emergency stop control, there are speed adjustment buttons placed on the machine that enables easy of use. Ergonomic, operator-friendly Human Machine Interface (HMI), it can be shown on the screen when material missing, splicing jointer, auto splicing of raw material, fan and vacuum pump tripping. The parameters of rejection position and quantities can be set on screen.

Operation and maintenance training is available at start-up and throughout the life of your baby diaper machines from SUNREE. All the machine testing period, our technicians will teach you to the spot, including correct operation, and maintenance knowledge. Our team provides on-site support to keep your underpad making machine up and running, remote assistance for real-time service is also provided to accelerate the troubleshooting process and minimize downtime.

Flexible underpad machine processes are custom designed to your specific requirements, it can run multiple widths and lengths with minimal part changes, multiple core forming options, including fluff or airlaid, and the underpad machine can fold underpad based on the packaging preferences.

We have helped customers in more than 60 countries to be successful and improve their qualification rates. We also welcome you to send an inquiry for your needs, let us make your demands come alive.

Tell us what kind of support you need, we will reach out to you within 1 working day, please pay attention to the email with the suffix “@sunreechina.com”.