BABY CARE

ADULT INCONTINENCE

DAILY CLEANING

- Wet Wipes Machine

- Compressed Towel Machine

- Bath Towel Machine

SPECIALTY

- Packaging machine

- Nonwoven Embossing Machine

- Nonwoven Perforating Machine

- SAP Paper Machine

A number of engineering and manufacturing innovations have dramatically improved the quality, performance, and convenience of feminine sanitary napkin, napkin pants and panty liner. SUNREE designed these machines can produce products at high speed while maintaining high quality and stable production.

| PRODUCT | SPEED (PPM) | |

| Panty Liner | 1000-1500 | |

| Sanitary Napkin | 500-1200 | |

| Period Panties | 300-450 |

By understanding your need, down to the smallest detail, then channel our activities in a responsible and reliable way to deliver tailor-made feminine hygiene product machines. This list represents base configuration machines, we have complete design capabilities and can meet every one of your specific requirements. Welcome to contact us now!

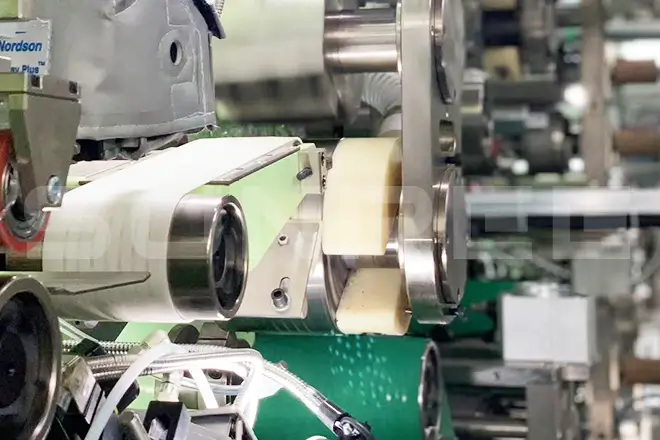

Feminine napkin tri-fold and packaging integrated production line, feminine napkin pant production line and pantyliner machine are efficient, easy to handle, and produce high output with big material savings, with an economical solution, a number of engineering and manufacturing innovations have dramatically improved the quality, performance and convenience of feminine hygiene products. SUNREE engineers work with you to customize features and functionality to meet your product and production requirements.

SUNREE provides a wide range of options to create the feminine hygiene product features you need. The absorbent core is available in fluff SAP core or premade SAP paper core, pouch easy wrap are available in nonwoven fabric, PE film or release film. Apply colors and patterns to your sanitary napkin with in-line printer.

Integrated with all machine processes and customized to feminine hygiene products being manufactured, the intelligent vision control system accurately detects defects and automatically eliminates sanitary napkins when sanitary napkin inconsistencies are detected, significantly reducing material waste and guaranteeing inspection at full production speed for consistent, repeatable quality.

With safety framework and cutter entrance safety cover, and emergency stop control, there are speed adjustment buttons placed on the machine that enables easy of use. Ergonomic, operator-friendly Human Machine Interface (HMI), it can be shown on the screen when material missing, splicing jointer, auto splicing of raw material, fan and vacuum pump tripping. The parameters of rejection position and quantities can be set on screen.

As production speeds increase, so does the demand for greater feminine hygiene product quality control. We need to flawless cuts at various critical stages of the production process to increase the efficiency of the inline-cutting processes to reduce waste with multiple web-cutting technologies, flex knives, slitting operations and die-cutting ensure speed and precision with minimal waste.

Flexible machine processes are custom designed to your specific requirements, modular design enables easy upgrades and retrofits. The stander of whole machine is using 60×60mm solid square steel, the six sides of panel are all under CNC treatment, with a thickness of 30mm.

We have helped customers in more than 60 countries to be successful and improve their qualification rates. We also welcome you to send an inquiry for your needs, let us make your demands come alive.

Tell us what kind of support you need, we will reach out to you within 1 working day, please pay attention to the email with the suffix “@sunreechina.com”.